Urban Service Station

Portable Smart Pod Expressway Intelligent Multi-function Service Cabin

- Category: Urban Service Station

- Views:91

- Dimension:12.8*2.8*3M

- Application: expressway

- Vacuum toilet qty: 3

- Main mateira: Aluminum

Portable Smart Pod Expressway Intelligent Multi-function Service Cabin

1. Brief introduction:

The "Smart Expressway Service Cabin" is a comprehensive upgrade from traditional service areas. By leveraging modern information technologies such as the Internet of Things (IoT), Big Data, Artificial Intelligence (AI), and Cloud Computing, it aims to provide travelers with safer, more convenient, more comfortable, and more diverse services. Simultaneously, it seeks to reduce operational costs, improve efficiency, and achieve green and sustainable development.

The smart expressway service pod has two functional modules: free restroom facilities and self-service commercial offerings. This innovative "Commerce-Subsidized-Restroom" model provides convenience for travelers while simultaneously stimulating consumption and increasing revenue.

2. Main functions of smart expressway service cabin:

2.1. Smart Restroom Services:

- Free Access: Provides three complimentary toilet stalls for travelers.

- Vacuum Technology: Utilizes smart vacuum-flush systems to achieve 90% water savings.

- Intelligent Management: Automatically monitors occupancy and adjusts environmental conditions (e.g., ventilation, lighting).

- Dual Benefits: Ensures convenient and hygienic facilities for users while minimizing manual maintenance costs.

2.2 Commercial Business Module:

- Unmanned Supermarket: Generates profit through the unattended retail of snacks, general goods, beverages, and charging services.

- Advertising Revenue: Features an LED information display screen for commercial advertisements, creating an additional revenue source.

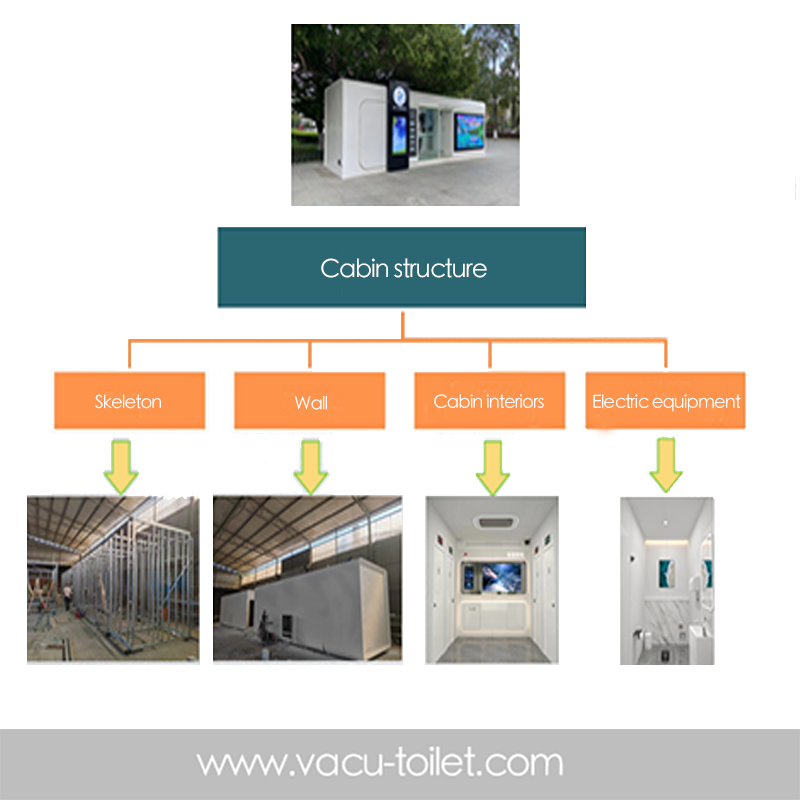

3. The implementation process of the Smart Service Cabin involves the following key stages:

- Requirements Analysis: The theme and primary functions of the Smart cabin are defined based on the foot traffic at the deployment site and the surrounding competitive landscape.

- Solution Design: This phase involves creating the overall layout and designing the business model.

- Factory Production: The unit's main frame is constructed from welded steel, and the body is built using aluminum plates. All electrical systems and various equipment are installed at this stage.

- Assembly & Debugging: All subsystems are integrated, software is configured, and comprehensive system testing and debugging are conducted.

- Shipping & Deployment: The finished unit is transported to the designated site by road or sea and is commissioned for operation.

Products Category

Latest News

CONTACT US

Name:

Mobile:+86-13222235952

Tel:+86-13222235952

Email:sales@to-rail.com

Add:Room B1701, Building 4, Dongfang Xintiandi, Yangshe Town, Zhangiiagang City, Suzhou City. Jiangsu Province, China, Zipcode:215617